Hyléance Beauty represents the new beauty division of the Hyléance Group, an expert in plastic transformation for various industries, including packaging.

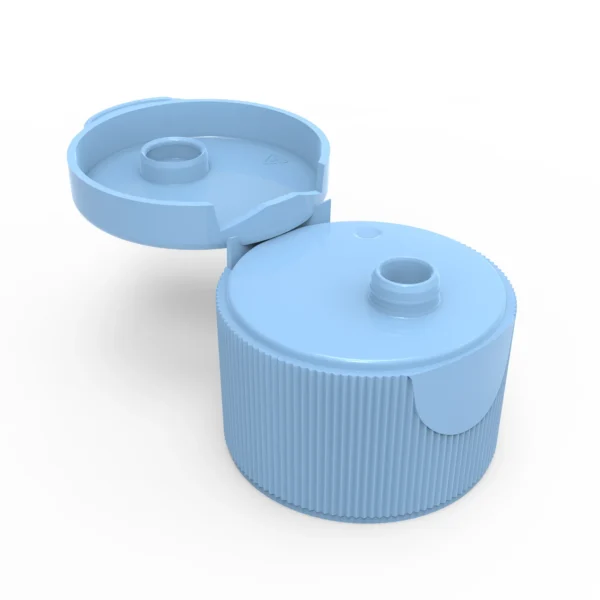

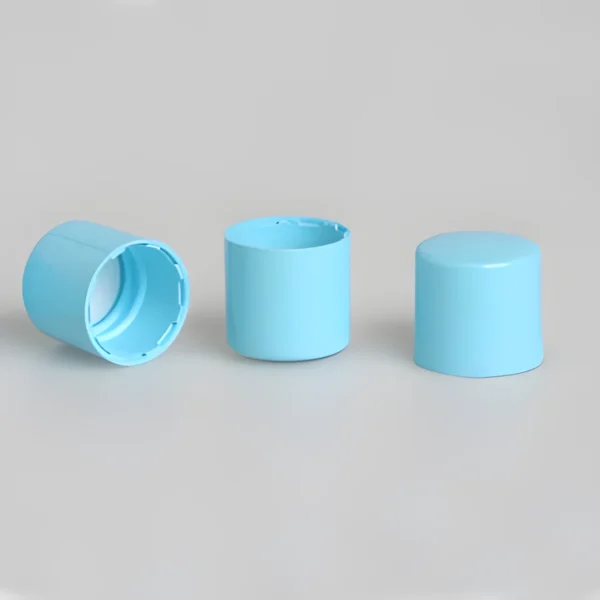

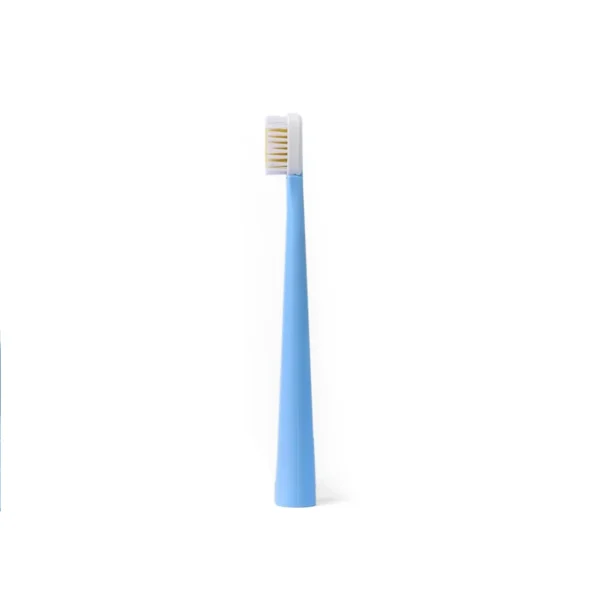

This division focuses on the development of 3R eco-designed, sustainable, and responsible products for the cosmetics, hygiene, and healthcare sectors, spearheaded by an exclusive range of refillable products, with three standard references available to date.

EN

EN